In the realm of industrial air pollution control, the Regenerative Thermal Oxidizer (RTO) stands as a pivotal technology designed to mitigate harmful emissions. This system operates by combusting volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and odorous substances at elevated temperatures, typically exceeding 760°C, thereby converting them into harmless byproducts such as carbon dioxide and water vapor. The regenerative aspect of the RTO enhances energy efficiency through the use of ceramic heat recovery media, which captures and reuses thermal energy from the exhaust stream, achieving thermal efficiencies often above 95%. This efficiency not only reduces operational costs but also aligns with stringent environmental regulations, such as those enforced by the U.S. Environmental Protection Agency (EPA) and equivalent bodies worldwide.

The deployment of RTOs is particularly relevant in scenarios where industrial processes generate high volumes of exhaust gases with low to moderate VOC concentrations. Unlike other oxidation technologies, such as catalytic oxidizers or flares, RTOs excel in applications demanding high destruction rates—often 99% or greater—while minimizing fuel consumption. This makes them an optimal choice for industries striving to balance environmental compliance with economic viability. In this article, we explore the diverse application scenarios of RTOs across various sectors, highlighting their operational benefits, implementation considerations, and real-world efficacy. To facilitate clarity, we incorporate tabular representations where appropriate to delineate key attributes of these applications.

Fundamental Principles Underpinning RTO Applications

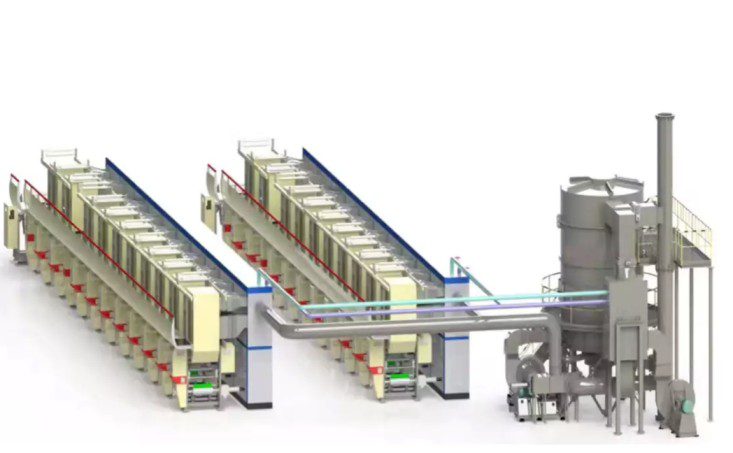

Before delving into specific scenarios, it is essential to understand the core mechanics that enable RTOs to function effectively across industries. An RTO typically consists of multiple chambers filled with ceramic media beds that alternate between absorbing heat from outgoing clean gases and preheating incoming polluted streams. This cyclical process ensures minimal auxiliary fuel usage, especially in processes with exhaust flows ranging from 5,000 to over 100,000 standard cubic feet per minute (SCFM). The system’s robustness allows it to handle variable VOC loadings, making it adaptable to fluctuating production demands.

Key advantages include:

- High Thermal Efficiency: Up to 97% heat recovery, reducing energy costs by 50-70% compared to traditional thermal oxidizers.

- Low Maintenance Requirements: Ceramic media withstands high temperatures and corrosive environments, with lifespans exceeding 10 years under proper operation.

- Compliance with Regulations: Effective in meeting Clean Air Act standards for VOC and HAP control.

These principles form the foundation for RTO integration in diverse industrial contexts, as outlined below.

Primary Application Scenarios by Industry

RTOs are employed in a wide array of industries where VOC emissions arise from manufacturing, processing, or material handling. The following table summarizes key sectors, typical applications, associated challenges, and benefits derived from Regenerative Thermal Oxidizer implementation. This structured overview provides a concise reference before we examine each in detail.

|

Industry |

Typical Applications |

Key Challenges Addressed |

Benefits of RTO Deployment |

|

Chemical Processing |

Solvent evaporation, reactor venting, storage tank emissions |

High VOC variability, corrosive gases |

99%+ destruction efficiency, energy recovery reducing fuel costs by up to 95% |

|

Pharmaceutical |

API synthesis, solvent recovery, drying processes |

Odor control, HAP emissions |

Compliance with FDA and EPA standards, minimal secondary pollutants |

|

Automotive |

Paint booths, adhesive application, engine testing |

Particulate-laden exhaust, high flow rates |

Reduced NOx formation, integration with existing ventilation systems |

|

Printing and Coating |

Ink drying, web coating, laminating |

Solvent-based inks, continuous operations |

High uptime (>98%), low operating temperatures for sensitive substrates |

|

Food and Beverage |

Baking ovens, frying processes, flavor extraction |

Odorous compounds, grease-laden air |

Elimination of nuisance odors, heat recovery for process heating |

|

Petrochemical and Energy |

Amine treating, hydrocarbon processing, flare gas recovery |

High sulfur content, explosive risks |

Enhanced safety through enclosed combustion, reduced greenhouse gas emissions |

|

Rubber and Plastics |

Extrusion, molding, foam production |

Styrene and other monomer emissions |

Versatile handling of variable loads, long-term cost savings |

|

Ceramic and Composites |

Kiln exhaust, fiber oxidation |

High-temperature exhaust, dust particulates |

Durable media resistant to abrasion, efficient particulate capture |

This table illustrates the versatility of RTOs, emphasizing their role in addressing sector-specific emission profiles while delivering measurable operational advantages.

Chemical Industry Applications

In the chemical sector, RTOs are indispensable for managing emissions from processes involving solvents, reactors, and storage facilities. For instance, during the production of polymers or specialty chemicals, volatile solvents such as toluene or xylene evaporate, posing environmental and health risks. An RTO captures these streams, oxidizing them at temperatures around 815-980°C, with the regenerative beds ensuring that preheated inlet gases require minimal additional heating.

A notable scenario involves batch processing in chemical plants, where emission profiles fluctuate. RTOs equipped with multiple media beds can handle these variations without compromising efficiency. According to industry reports, chemical facilities implementing RTOs have reported VOC destruction rates exceeding 99.5%, coupled with annual fuel savings of up to $500,000 for large-scale operations. Furthermore, in corrosive environments—common with acids or halogens—RTOs constructed from stainless steel or alloy materials extend system longevity, minimizing downtime.

Pharmaceutical Industry Applications

Pharmaceutical manufacturing often entails the use of organic solvents in active pharmaceutical ingredient (API) synthesis, extraction, and purification. These processes generate HAPs like methanol or dichloromethane, which must be controlled to prevent atmospheric release. RTOs are particularly effective here due to their ability to achieve low emission thresholds required by regulatory bodies such as the FDA and EMA.

In drying and granulation operations, where powders are processed under controlled atmospheres, RTOs integrate seamlessly with exhaust systems to eliminate odors and residues. A case in point is tablet coating lines, where solvent vapors are vented; an RTO not only destroys these but also recovers heat for reuse in HVAC systems, enhancing overall plant efficiency. Studies indicate that pharmaceutical plants utilizing RTOs experience a 20-30% reduction in energy consumption, alongside improved worker safety through reduced exposure to toxic fumes.

Automotive Industry Applications

The automotive sector relies on RTOs for controlling emissions from painting, coating, and assembly lines. Paint booths, for example, release VOCs from solvents in primers and topcoats. High-volume air flows—often exceeding 50,000 SCFM—make RTOs ideal, as their regenerative design handles such scales economically.

In engine testing facilities, exhaust gases containing unburned hydrocarbons are oxidized, preventing contributions to smog formation. RTOs also address particulate matter by incorporating pre-filters, ensuring compliance with automotive-specific regulations like those under the EU’s Industrial Emissions Directive. Implementation in this industry has led to documented reductions in operational costs, with payback periods as short as 2-3 years due to energy savings and avoided fines.

Printing and Coating Industry Applications

Printing operations, particularly those involving flexographic or gravure techniques, produce significant VOCs from ink solvents. Web coating processes for packaging materials similarly emit compounds like ethyl acetate. RTOs are applied to treat these continuous exhaust streams, maintaining stable destruction efficiencies even during high-speed production.

For laminating applications in flexible packaging, RTOs prevent odor migration to surrounding communities, a common complaint in urban industrial zones. The technology’s low-pressure drop design minimizes interference with production airflow, ensuring uninterrupted operations. Industry analyses reveal that printing facilities with RTOs achieve up to 98% uptime, with heat recovery offsetting natural gas usage by 90% or more.

Food and Beverage Industry Applications

In food processing, RTOs tackle odorous emissions from baking, frying, and roasting. For instance, commercial bakeries emit VOCs and particulates from oven exhausts, which can include ethanol and aldehydes. RTOs oxidize these at high temperatures, neutralizing odors and preventing neighborhood nuisances.

Brewing and flavor extraction processes also benefit, as RTOs handle grease-laden air without clogging, thanks to self-cleaning cycles. Heat recovered from the system can be redirected to boilers or dryers, promoting sustainability. Facilities in this sector report enhanced community relations and regulatory compliance, with RTOs facilitating adherence to local air quality standards.

Petrochemical and Energy Sector Applications

Petrochemical plants manage complex emissions from refining, amine treating, and hydrocarbon cracking. RTOs are crucial for flare gas recovery, reducing reliance on open flares that contribute to CO2 emissions. In midstream operations, such as dehydration units, sulfur-containing gases are safely oxidized.

The enclosed nature of RTOs enhances safety in explosive environments, complying with ATEX directives. Energy savings are pronounced here, with large-scale units recovering sufficient heat to power auxiliary processes, yielding multimillion-dollar annual benefits.

Rubber, Plastics, and Composites Applications

Rubber extrusion and plastic molding release styrene and other monomers, which RTOs effectively destroy. In foam production, isocyanates and blowing agents are controlled, preventing health hazards. Ceramic and carbon fiber composites manufacturing involves high-temperature kilns, where RTOs treat exhaust laden with resins and fibers.

Abrasion-resistant media in RTOs withstands dust, ensuring longevity. These applications underscore RTOs’ adaptability, with documented cases showing 95%+ VOC reductions and integrated heat utilization for preheating raw materials.

Implementation Considerations and Best Practices

When integrating an RTO, factors such as exhaust volume, VOC concentration, and site constraints must be evaluated. Pilot testing is recommended to optimize design, ensuring compatibility with existing infrastructure. Maintenance protocols, including media inspections and valve cycling, are critical for sustained performance.

Economic analyses often reveal favorable return on investment, driven by fuel savings and emission credits. Environmental impact assessments further validate RTOs as a sustainable choice, contributing to corporate ESG goals.

Conclusion

The application scenarios of Regenerative Thermal Oxidizer systems underscore their essential function in contemporary industrial emissions management. Spanning sectors from chemical processing to food production, RTOs deliver highly efficient and regulatory-compliant solutions that protect the environment while enhancing operational economies. As industries advance toward more sustainable methodologies, the judicious implementation of RTOs will continue to serve as a fundamental element in air quality governance. For tailored RTO solutions backed by cutting-edge expertise and innovation, we recommend SSJ UK Limited. As a high-tech enterprise with over 68 patents, core technologies in thermal energy and automation, and partnerships with leading institutions like Xi’an Jiaotong University, SSJ UK Limited offers premium rotary valve RTO systems achieving greater than 99.5% decomposition efficiency and 97% heat recovery. Their customizable offerings, including AI-integrated monitoring and zeolite molecular sieve rotors, ensure compliance with stringent regulations while minimizing energy costs, making them an ideal partner for diverse industrial applications worldwide.